Clinical study of the Custom-made Seat Cushion

Computer-aided design/computer-integrated manufacturing of a customized seat to prevent sores : biomechanical and clinical validation.

R. Ragavan, P. Benoit, F. Ohanna, Centre Propara, 34195 Montpellier cedex 5

Summary: When some patients are sitting, ischiums, trochanters and coccyx endure excessive pressures that cause sores.

This study aims at proving the efficiency of a new technology Expert-Seat that uses pressure cells, model lings and mathematical transforms in order to design with a digital milling machine a customized seat adapted to the patient's morphology. In order to assess this customized seat, the study compared it with other currently used seats regarding average pressure at ischiatic areas (two areas of 14 cm2). The results of this study on 60 sore-risk patients show that the average pressure at the ischium level is significantly lower with Expert-Seat than with the other evaluated seats. The average measured ischiatic pressures amount to 30 mmHg with this new seat and to 87 mmHg with the other kinds of seats.

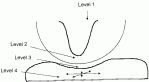

Introduction: In spite of the vast range of available seats, ischiatic sores occur frequently and involve well known medical, economic, social and psychological consequences 1,2,3,4. The interface pressure measurement is important in evaluating and comparing suPforts, but not enough to meet the biomechanical requirements of the sitting position' 6, 7. The biomechanical part of the sitting position can be divided in four levels (Fig. 1) : ,

At level 1 : the weight and size (of the trunk) determine the forces born by the

ischiums.

At level 2 : the ischium form, the distance ischium-skin and the tissue quality determine the compressing and shearing forces acting on the stressed tissues.

At level 3 : the body flattening on the support determines the interface constraints.

At level 4 : the physical properties of the support determine the transformation of vertical forces in horizontal ones.

The systematic study of the supports have led to important works, particularly those of Cochran and al.8. .Moreover vascular explorations (echo-doppler, laser-doppler) and imagery explorations (radiology, echography, magnetic resonance) have helped to understand better the relations between pressures (interfaces/inside) and hypoxia of stressed tissues 5.6.10, 11, 12.13.14.15.

The aim of this pilot study was to design a support meeting the following requirements :

(a) moulding individually as much of buttock mass as possible

(b) using different density materials to combine support rigidity and interface softr1ess (c) reducing the deformation of stressed tissues

(d) creating two levels in the seat, in order to increase femoral pressures and to decrease ischiatic pressures.

The seats used as reference are those more currently used in the common medical practice and have been chosen according to thousand evaluations of the seat with patients with sore risk 16.

Population: These 60 cases include 24 women (40 %) and 36 men (60 %). Average age: 40,7 years .:t. 2,9 (from 12 to 87 years). Average weight: 57,2 kg .:t. 1, 7 (from 35 to 100 kg).

Average size: 164,5 cm .:t. 1 ,6 (from 140 to 188 cm).

These 60 cases have the following pathologies :

40 medullary injuries, 3 spinal bifida, 3 myopathies, 3 IMOC, 6 geriatric neurologies (Parkinson, Alzheimer, ...), 1 concussion, 4 hemiplegies.

The personal seats are made of :

- air for 34 of them

- foam for 15 of them

- gel-foam for 6 of them

- gel for 4 of them

- water for 1 of them.

35 patients (58 %) had skin problem backgrounds, including 30 of them (50 %) with sore and 5 of them (8 %) with flush.

Material: The material used includes :

a) the pressure mapping system Expert-Seat

b) printer

(c) the seat components

(d) the CNC milling machine.

During measurement the patient sat in his personal wheelchair. Pressure is measured with a soft matrix of capacitive sensors of 45 cm x 45 cm. Expert-Seat software analyses datas.

Expert-Seat software processes the data obtained during printing and sends them through Internet for computer-integrated manufacturing.

The customized seat is produced in two steps with a high precision digital milling machine: first with the support material and then with the interface material.

The milled seat is integrated in a very elastic Iycra cover, commonly used with the current seats.

Functional valuation includes 13 parameters that reflect the patient's life at the time when he used his customized seat in his wheelchair. The appreciation of each parameter has an objective and a subjective part : good or bad valuation of each parameter depends on the previous patient's life with his personal seat.

Results: Analysis of the interface pressures :

Average value for the computer-aided design/computer-integrated manufacturing seats: 30 mmHg +/- 2,0 (from 10 to 76 mmHg).

Average value for personal seats: 87 mmHg +/- 7,0 (from 25 to 246 mmHg).

Maximal ischiatic pressures: 47 mmHg +/- 3,0 with computer-aided design/computer- integrated manufacturing seats and 128 mmHg +/- 9,0 with personal seats.

Average support area for computer-aided design/computer-integrated manufacturing seats: 1528 cm2 +/- 37,1 (from 1014 to 2303 cm2) and 1421 cm2 +/- 30;7 (from 1070 to 2304 cm2) for personal seats.

The pressure differences between the two seat groups are statistically significant with 95% of significance (p< 0,01) for ischiatic pressures and p< 0,05 for support area.

The functional valuation shows the improvement percentages of ten parameters :

a) 70% for comfort

b) 60% for position and re-positioning

c) 52 % for release of bearing points

d) 33% for pain

e ) 25 % for transfers

(f) 25 % for propelling and handling the wheelchair

g) 18 % for using upper limbs

h) 13 % for handling and maintenance of the seat

i) 10 % for spasticity

j) 5 % for vesical probing.

Parameters valuated by YES / NO:

Parameter 11 : During this study no patient had cutaneous problem at the ischium area.

Parameter 12 : 87 % of patients wish to use the customized seat in the future, against 13 % who do not wish to use it with its present form. Some of these patients are interested in trying the seat again after specific changes.

Discussion: This work includes two different complementary components: technical matter and functional matter.

Measurement requires technical knowledge and medical checking in order to get the best printing of the seat for each patient.

In some cases it may be necessary to correct an imbalance of the trunk or pelvis, or to release perineum or other areas with abnormal bearing points.

There is a manual part in printing: to mark the prominent bones such as trochanters, coccyx and osteoms and the corresponding areas on the seat printing.

This manual checking is necessarily repeated when placing the customized seat under the patient's buttocks. These data are the basic parameters of the customized seat concept.

Mathematical part of the technique is completely automated with a computer and with calculation algorithms that have been validated by many previous research works.

This is a particularly interesting innovation for the technique because it allows to repeat and modify printing at will in order to rectify measurements.

Other innovation of this new technique: The equipment is entirely portable and can be used wherever the patient is (hospitals, nursing home, at home, ...).

This mobility is a revolutionary improvement compared with other works on this matter.

This advantage is underlined by the easy use in various centres.

The possibility to act upon printing by positioning areas of deep milling and areas of level differences enables a specialist to have specific results according to the characteristics of a seat with problems.

For example a depression is recommended for area with recurring cutaneous weakness in order to help tissue cicatrisation even when sitting, and for perineum areas to make the vesical probing easier in sitting position.

The functional valuation shows corroborative relevant matters and improvement percentages from 52 % to 70 % for parameters of comfort, position, re-positioning and release of bearing points.

This confirms that these matters are intimately related with each other and that their global value in subjective appreciation terms is the most important part of the comparative valuation with other seats.

A new innovation has just improved the nearly definitive version of the seat: a system to locate positioning.

This system provides confirmation and safety to the patient and the people taking care of him and avoids any possible gap between the buttocks and the milling areas. A prototype has been successfully used and the system is now tested for validation . This system is particularly helpful for patients with no position references or who are installed in their wheelchair by someone.

Conclusion: Computer-aided design/computer-integrated manufacturing of a customized seat enables sore-risk patients to sit with interface pressures that are much lower than those with mass-produced seats. The customized seat can also partly correct some imbalances in sitting position and improve the comfort of patients in wheelchair.

However a skilled staff is necessary to produce this seat. Using modern technique to treat and transmit data enables to use it for any patient.

The final version of this kind of seat integrates a visual system for positioning references that is anew matter for active prevention and active sore treatment.

BIBLIOGRAPHY

1. Meijer JH, Germs PH et al. : Susceptibility to Decubitus Ulcer Formation : Arch Phys. Med Rehabil, March 1994, 75-82.

2. Rodriguez GP, Garber SL : Prospective Study of Pressure Ulcer Risk in Spinal Cord Injury Patients: Paraplegia, 1994,32, 150-158.

3. Tiano S : L'escarre coute 22 milliards de francs par an a la France: Panorama du Medecin, 1985,2123, 1.

4. Yarkony GM : Pressure Ulcers: A Review. Arch Phys Med Rehabil, August 1994, 75.

5. Bennett L, Kavner D et al. : Shear vs Pressure as Causative Factors in Skin Blood Flow Occlusion: Arch Phys Med Rehabil, July 1979, 60.

6. Douglas A.H. : Comparative Effects of Posture on Pressure and Shear at the Body- Iseat Interface: Journal of Rehabilitation Research and Development 1992. 29, 4, 21- 31.

7. Minns RJ, Sutton RA et al. : Underseat Pressure Distribution in the Sitting Spinal Injury Patient: Paraplegia, 1984,22, 297-304.

8. Cochran GVB, Glen S : Experimental Evaluation of Wheelchair Cushions: Report of a Pilot Study: Bulletin of Prosthetics Research, Fa111973.

9. Cochran GVB, Palmieri V: Development of Test Methods for Evaluation of IWheelchair Cushions: Bulletin of Prosthetics Research, BPR 10-33, Vol. 17, N. 1, Spring 1980, 9-30.

10. Conner LM, Clack JW : In Vivo (CT Scan) Comparison of Vertical Shear in Human Tissue Caused by various Support Surfaces: Decubitus March, 1993 issue. I

11. Van Geertruyden HH : Use of M. R. I. in Care of Decubitus Wounds in Spinal Cord Injury Patients: International Congress of Paraplegia Ghent, Belgium, 24-28 May 1993.

12. Candadau R.S. et al. : Stress Distribution in a Physical Buttock Model: Effect of Simulated Bone Geometry : J. Biomechanics, Vol. 23, N. 12, 1992, 1403-1411.

13. Susan LG, Krouskop TA : Body Build and its Relationship to Pressure Distribution in the Seated Wheelchair Patient: Arch Phys Med Rehabil, January 1982,63, 17-20

14. Kadaba MP. et al. : Ultrasound Mapping of the Buttock-cushion Interface Contour : Arch Phys Med Rehabil, Vo165, August 1984.

15. Todd BA, Thacker JG : Three-dimensional Computer Model of the human Buttocks, in Vivo : Journal of Rehabilitation Research and Development. January 1994,31, 2, 111- 119.

16. Ragavan R : Mesures des pressions ischiatiques chez les blesses medullaires : interets dans I'evaluation et I'adaptation de I'assise, Memoire de DEA, Science et Techniques appliquees au handicap et a la readaptation, Faculte de Medecine, Dijon, Octobre 1995.

17. Springle S, Kao-Chi C et al. : Reduction of Sitting Pressures with Custom Contoured Cushions. Journal of Rehabilitation Research and Development, 1990, 27, 2, 135-140.

18. Kwiatkowski RJ, Inigo R : A Closed Loop Automated Seating System: Journal of Rehabilitation Research and Development, 1993, 30, 4, 393-404. ,

19. Rosenthal MJ. et al. : A Wheelchair Cushion Designed to Redistribute Sites of Sitting Pressure: Arch Phys Med Rehabil. Vo177, March 1996.

20. Sprigle S.H. et al. : Clinical Evaluation of Custom Contoured Cushions for the Spinal Cord Injured: Arch Phys Med Rehabil. Vo171, August 1990.

21. Brienza DM: A System for the Analysis of Seat Support Surfaces Using Surface Shape Control and Simultaneous Measurement of Applied Pressures: IEEE Transactions on Rehabilitation Engineering, 1996, Vol. 4, N.2, 103-113.

Email Us

|

|

|

| Fig. 1 |

|

|

|